If you are in the trucking industry, you must have come across the term ‘reefer trailer’. But what is a reefer trailer exactly? In simple terms, a reefer trailer is a refrigerated trailer equipped with a trailer refrigeration unit that helps maintain a controlled temperature for transporting perishable goods. From fresh produce to pharmaceuticals, reefer trailers keep products in pristine condition throughout their journey.

In this blog, we will break down what a reefer trailer is, how it works, why reefer fuel matters, and how TruckX’s technology can enhance your operations with solutions like Smart Asset Trackers, and Temperature and Humidity monitoring.

What is a Reefer Trailer?

A reefer trailer, short for ‘refrigerated trailer,’ is designed to transport temperature-sensitive goods. Unlike regular dry vans, reefer trailers are equipped with reefer units – a refrigeration system that keeps the trailers at a specific temperature. These trailers are required for industries transporting perishable items, including fresh produce, frozen foods, pharmaceuticals, flowers, and chemicals.

The ability to control the environment inside a refrigerated trailer makes it an indispensable tool in supply chains. Whether it is keeping ice cream frozen or medicines effective, reefer trailers are the backbone of cold chain logistics.

How Does a Reefer Trailer Work?

Understanding how a reefer trailer operates helps you appreciate its value. The trailer refrigeration unit is at the core of the refrigerated trailer, which functions similarly to a household refrigerator but on a much larger scale.

1. Trailer Refrigeration Unit

The reefer refrigeration unit consists of three main components:

- Compressor: It compresses the refrigerant gas, raising its pressure.

- Condenser: Converts the refrigerant gas into a liquid by cooling it.

- Evaporator: Absorbs heat from inside the trailer, reducing the temperature.

This closed-loop system keeps the air circulating, ensuring an even and consistent temperature inside the trailer.

2. Insulated Design

Reefer trailers are built with walls, floors, and ceilings made of metal or fiberglass to help insulate the trailer and prevent external heat or cold from affecting the cargo. This insulation plays a key role in maintaining efficiency and reducing energy consumption.

3. Reefer Fuel

The trailer refrigeration unit runs on a separate power source which is usually diesel fuel, commonly referred to as ‘reefer fuel ‘. It is a special type of ultra-low sulfur diesel (ULSD) used specifically for powering reefer units, ensuring the cargo stays at the right temperature during transit.

Why is Reefer Fuel Important?

Without reefer fuel, the reefer unit cannot function, putting the cargo at risk. Here is why reefer fuel is essential:

- Temperature Consistency: A steady supply of reefer fuel ensures the refrigeration system runs uninterrupted, maintaining the desired temperature throughout the journey.

- Compliance: Proper use of reefer fuel ensures the unit meets environmental standards, reducing emissions.

- Operational Efficiency: Monitoring fuel levels helps optimize costs and prevent downtime due to unexpected fuel shortages.

Advantages of Using Reefer Trailers

Investing in a refrigerated trailer can bring significant advantages to your trucking business:

1. Broader Freight Opportunities

Reefer trailers allow you to transport high-demand, temperature-sensitive goods. From grocery stores to medical facilities, there is always a need for reliable refrigerated transport.

2. Higher Pay Rates

Transporting perishable goods often comes with better pay due to the added responsibility and specialized equipment required.

3. Cargo Protection

With a trailer refrigeration unit, your cargo remains safe and intact, even during long hauls or extreme weather conditions.

4. Customer Trust

Shippers trust fleets with reefer trailers for handling delicate loads, leading to more contracts and repeat business.

Challenges of Reefer Trailer Operations

While reefer trailers offer numerous benefits, they also come with unique challenges:

1. Higher Maintenance Costs

The reefer unit requires regular maintenance to ensure smooth operation. Compressors, condensers, and evaporators need timely inspections to avoid breakdowns.

2. Fuel Costs

Operating the trailer refrigeration unit adds to fuel expenses. Monitoring reefer fuel usage is key to managing costs effectively.

3. Strict Compliance

Transporting perishable goods involves strict temperature regulations. Carriers must maintain adequate temperature controls and monitor temperature stability. They must also keep records of transportation conditions for 12 months.

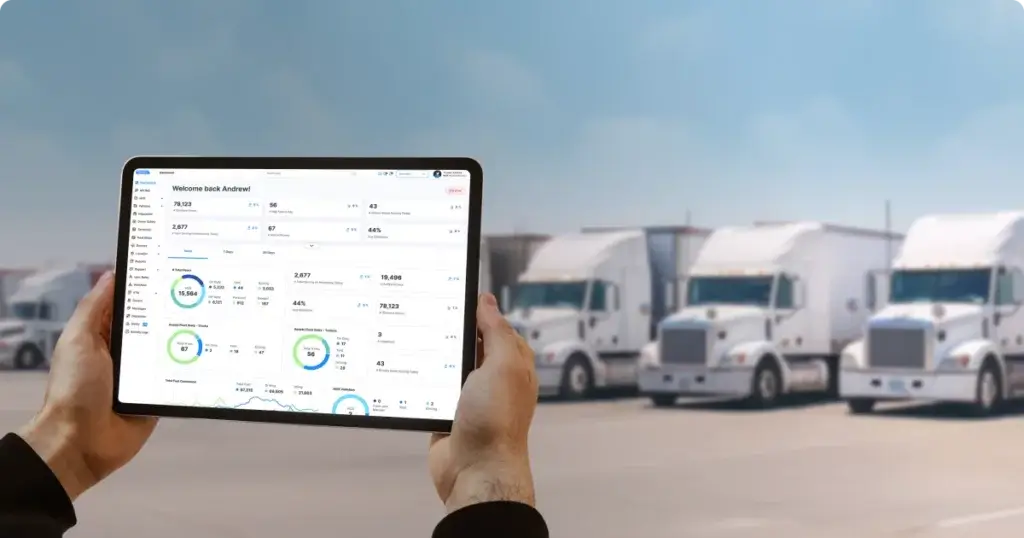

How TruckX Helps Reefer Trailer Operations

TruckX offers Temperature & Humidity sensor solutions to help owner-operators and fleet managers optimize reefer trailer operations. Our Temperature & Humidity sensors are specifically designed to monitor the conditions inside the refrigerated trailer in real-time and provide you with real-time data and alerts as well as historical reporting for quality control.

1. Real-Time Temperature Monitoring

TruckX’s sensors pair with a compatible TruckX Asset Tracker via Bluetooth. The Sensor has its own SIM card, allowing not only 24/7 live location tracking, but also real-time temperature and humidity tracking that provides alerts every 5 minutes and gives real-time updates on the temperature inside the reefer trailer, ensuring compliance with industry standards. If the temperature fluctuates, It gives instant alerts, allowing you to act before cargo is compromised.

2. Humidity Tracking

TruckX’s humidity sensors allow you to monitor and control the humidity levels inside your trailer, an essential feature for perishable goods like produce or pharmaceuticals. The system sends alerts if humidity falls outside the required range, enabling you to take immediate action to prevent cargo damage.

3. Compliance Made Easy

TruckX’s fleet management platform provides in-depth and customizable temperature & humidity reports that can be easily downloaded or shared for audits and quality assurance. This ensures compliance and builds trusting long-term relationships with the customers.

4. Real-Time GPS Tracking

With real-time GPS integration, TruckX provides live location tracking of your refrigerated trailer. This ensures timely deliveries and allows you to adjust routes in real time based on traffic or weather conditions. Our customizable geofencing capabilities also send safety alerts when trailers enter or leave designated areas, adding an extra layer of security.

Tips for Managing Reefer Trailers

Here are some tips to get the most out of your reefer trailer:

- Regular Maintenance: Schedule routine checks for the trailer refrigeration unit to avoid unexpected breakdowns.

- Train Drivers: Educate drivers on the proper handling of reefer trailers, including monitoring temperature and responding to alerts.

- Invest in Technology: Equip your fleet with TruckX’s sensors, GPS trackers, and fleet management solutions for better control and efficiency.

Conclusion

A reefer trailer is vital for safely and efficiently transporting temperature-sensitive goods. From keeping food fresh to ensuring medicines remain effective, reefer trailers are essential for modern logistics.

TruckX is here to help you make the most of your reefer unit operations. With our innovative temperature and humidity sensors and trailer tracking solutions, we make managing refrigerated trailers easier than ever.

Ready to take your reefer trailer operations to the next level? Visit TruckX.com or call +1 (650) 600-6007 today to learn more about our solutions and how they can benefit your fleet!